Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

ABOUT US

- 20 experience

- 600+ Direct employees

- 100+ Senior technicians

- 100000 Floor space

-

-

See For Yourself

Manufacturing is one of our core competencies, KDD has been committed to providing high quality products for all oversea market. With more than 25 years of professional manufacturing experience, KDD cv joint, drive shaft, wheel hub bearings have been sold to more than 120 countries and regions around the world. We pride ourselves on top quality to provide durability, long-lasting product making KDD a world-class leading resource for all our customer’s needs in the AutomotiveParts Industry.

-

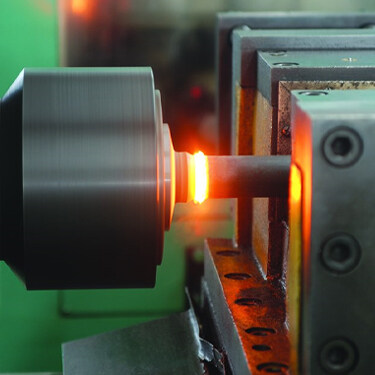

Do Even More

To assure high quality products, KDD attained the IATF 16949 international quality management system. At every stage during process, strict testing been excuted by experienced QC team.